PRODUCTS

PRODUCTS

ANALYSES

ANALYSES

RECIPES

RECIPES

PAPERS

PAPERS

REFERENCE

REFERENCE

|

Radio Frequency Heating. An interview with the simulation expert Pedro Vaca

Pedro Vaca, P.Eng. is a senior Reservoir Engineer with more than 30 years of experience

in Reservoir Simulation. After being involved in many engineering projects

in South America, Canada and USA, he currently works on modeling of

Radio Frequency Heating (RFH) processes for

Acceleware Ltd,

a leading Canadian Company in the electro-magnetic modeling

He kindly accepted our October 2014 invitation interview to share

his experiences in this field.

|

|

-

Could you describe the fundamental physical principles involved in RFH

(Radio Frequency Heating)?

The fundamental physical principle of the RFH is the capability of the

electro-magnetic (EM) waves to heat a lossy medium, i.e. a medium that can

dissipate the EM waves, such as the water, for example.

Everybody knows

that when you put a cup of coffee in the microwave oven, the coffee is heated.

In fact what is heated is the water contained in the cup.

The cup itself, which is usually made of ceramic or similar material,

is not heated by the EM waves, because the ceramic is a low loss material.

That's why you can take the cup with a bare hand and not get burned

in the process. The heat you feel in the cup is generated by oscillating

water molecules in the coffee.

The same thing happens in an oil reservoir.

All oil reservoirs contain water, so when you deploy an antenna in the

reservoir, the EM waves generated by the antenna will heat the water

of the reservoir and this water, in turn, will heat the oil.

Once heated, the oil has lower viscosity and is able to move to the

producing wells.

-

Which type of reservoirs would benefit from this exploitation technique?

Why would RFH be preferred over SAGD, Cyclic Steam Stimulation and other more

known thermal methods?

The initial target of this technology is any reservoir in which the steam

injection is difficult or impossible, such as thin reservoirs, very shallow

reservoirs (not allowing high pressure or not having a good cap rock),

highly heterogeneous reservoirs (with poor control of the steam chamber),

high water saturation reservoirs (with unfavourable mobility ratio), etc.

It is also considered as a means to accelerate the time to production with

steam process in specific cases. However, preliminary studies of energy

balance suggests that this technology

could even compete with some steam injection processes in more typical

reservoirs.

-

What petrophysical properties must the reservoir rock have to be amenable to RFH?

Besides classical properties like porosity, shaliness, water saturation,

would you need to model rock's dielectric constant?

Yes. Other that the usual petrophysical properties, we need to model two main

electrical properties of the medium: electrical conductivity and electrical

permittivity. Each reservoir has its own dielectrical properties and they need

to be measured in order for engineers to be able to predict the reservoir

behaviour correctly.

Importantly, these dielectrical properties change

with time, as they depend mainly on the reservoir temperature and

water saturation. Therefore, we need to measure these properties at

different temperatures and different water saturation values.

Our modeling tools are capable of incorporating these changes in the

simulation process.

-

Regarding the reservoir geometry and geology, is some confinement required,

like a cap rock in SAGD?

The SAGD process usually works at temperatures between 200 and 250 C. The

corresponding steam saturation pressure is 1600 and 4000 kPa. To properly

manage these pressures without any environmental problems (steam leaking to

the surface), you need a very competent cap rock.

In the case of the RFH

technology, the EM waves convert the water into steam when the temperature

reaches the steam saturation temperature, which depends on the reservoir

pressure. The steam will increase the pressure of the system, but not to

the same extreme of steam process that can

significantly affect the overburden.

So, in general, we

think this technology does not need to operate at such high pressures. But

in the case of very viscous oils, like in the Alberta Oil Sands, we will

probably also need some sort of competent cap rock if the temperature to

mobilize the oil needs to be much higher than the saturation temperature.

-

How effective is RFH to increase reservoir temperature. What temperature

increase might be expected after some time of "soaking"?

As mentioned before, RFH technology operates at the steam saturation

temperature; and this is reached very soon close to the antenna,

and more slowly as the distance from the antenna gets larger.

We don't do

"soaking". We usually operate in a continuous way and simulations done

with typical Alberta reservoir properties suggest that the temperature

generated with the antenna is able to produce an oil recovery similar and

in the same time as with a typical SAGD process.

-

What is the current state of simulation technologies for RFH process? Are

there commercial software suited for RFH?

We think that simulation technologies for the RFH process are already

mature. There are some tools already in the market and Acceleware

itself has developed a commercial package that integrates the EM simulator

and the reservoir simulator to properly and accurately simulate this

process.

Our simulation software is supported by its well recognized

expertise and experience in electromagnetic simulations. For example, most

cell phone antennas are designed with our software. A combination of three

areas of expertise is required for bringing a robust tool for RFH to

the market: EM simulation, reservoir simulation and High Performance

Computing programming, which are all our strong suits. Of course,

for modeling the RFH process, we also need other auxiliary tools, such as

petrophysical software, PVT packages, etc.

-

Are there some successful oil fields which have been exploited through RFH?

While the concept of RFH

was tested in the 70's and 80's without much

commercial success, the new interest in it results from the slow

disappearance of easy oil and maturity of RFH modeling tools.

There are press releases indicating a

success of initial tests performed by the ESEIEH Consortium in Alberta,

but not many details are released. We are aware of other ongoing

tests. We are also conducting some pilot projects, but it is premature to

identify the full extent of benefits that can be obtained from the technology. But

we are very encouraged by the results so far, and about the significant potential of

the technology.

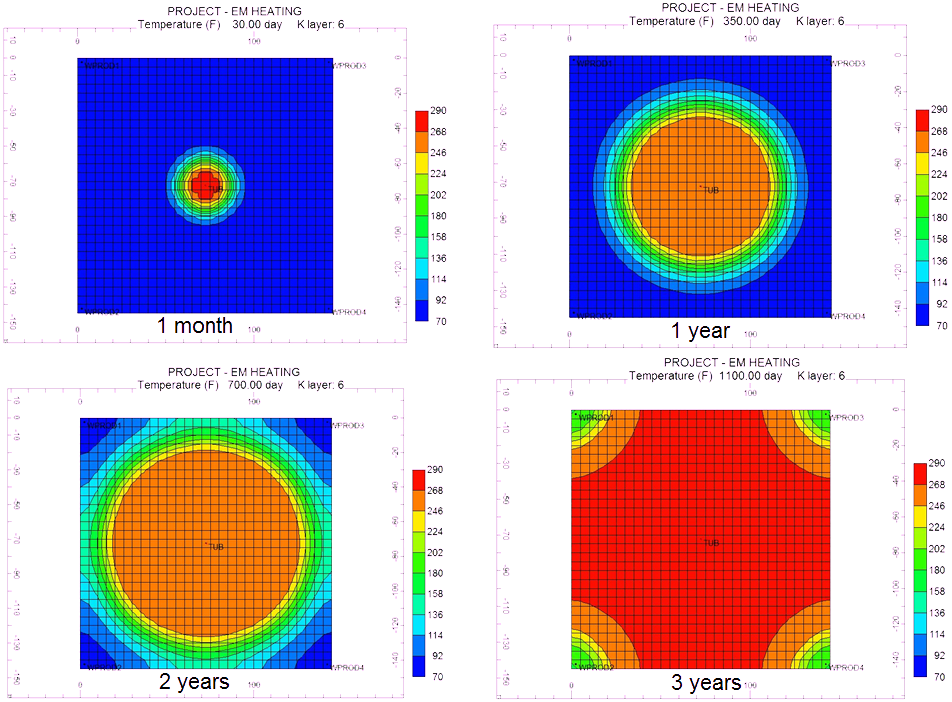

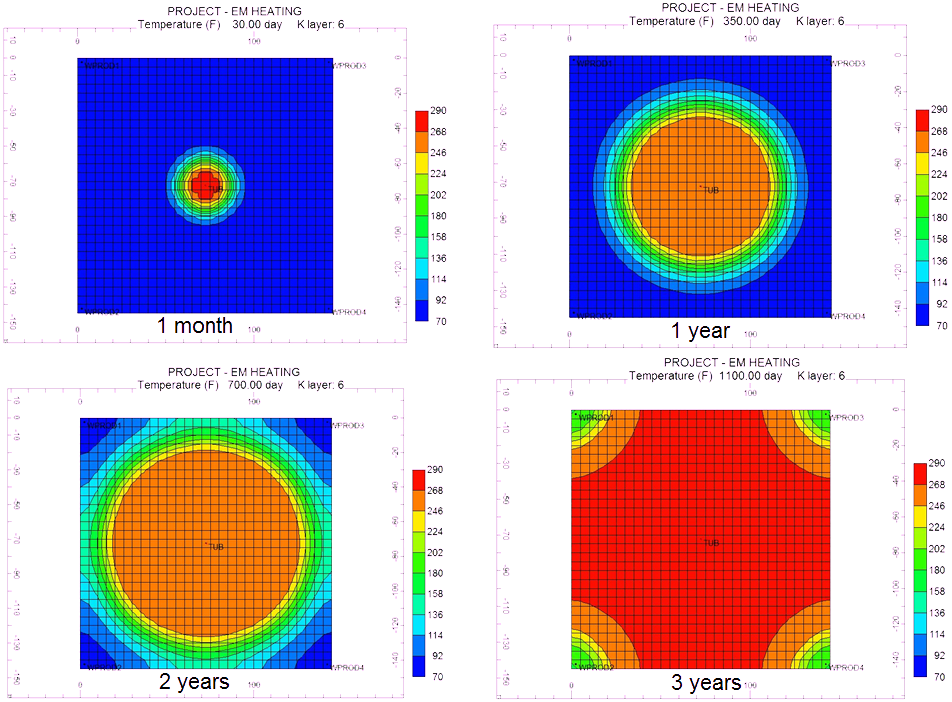

The figure below shows how applying RFH for three years succeeds to heat a reservoir region to ease its exploitation

|

|